Research

Mechanics of fiber reinforced laminated composites

Fiber reinforced laminated composites have gained much momentum in structural and aerospace applications due to their low weight to strength ratio. In our lab, we develop theoretical and numerical models to understand different properties and phenomena in composite materials. Progressive damage in laminated composites is of particular interest. Currently, an experimental lab for composite materials is under development where these materials will be tested for the verification of the developed models.

In recent years, a novel upper-triangular (QR) decomposition has been proposed to describe the kinematics of a finite deformation. This decomposition has several advantages especially with the ease of computation and experiments. The objective of our research group is to implement this novel method to solve problems in finite deformation elasticity, plasticity and viscoelasticity. This technique has already been proved to be useful in delineating an experimental method to measure physically relevant quantities such as, plastic component of the stretch tensor. We are looking to set up these experiments in order to utilize the full potential of this novel method.

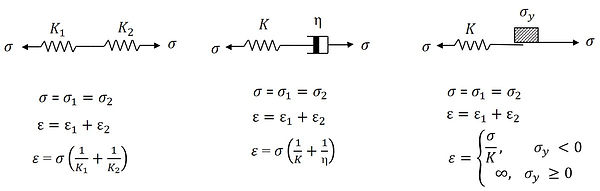

Viscoplastic behavior of materials is not well understood as compared to other material behaviors such as elasticity, plasticity, damage, viscoelasticity etc. Most of the existing viscoplastic material models are phenomenological and based on experimental data. our goal is to understand the physics behind the viscoplastic material behavior and correlate the theoretical models with the phenomenological ones. We use classical rheological elements as well as finite deformation theory such as a multiple natural configurations framework to develop effective, physics-based viscoplastic material models.

Research projects

-

Assessment and modeling of damage in fiber reinforced laminated composites for large deformation processes using multicontinuum theory and experiments

Sponsor: SERB, New Delhi Duration: 2023-2025

-

Analysis and modelling of mechanical damage in fiber reinforced laminated composites using multi-continuum theory.

Sponsor: IIT Roorkee Duration: 2023-2025